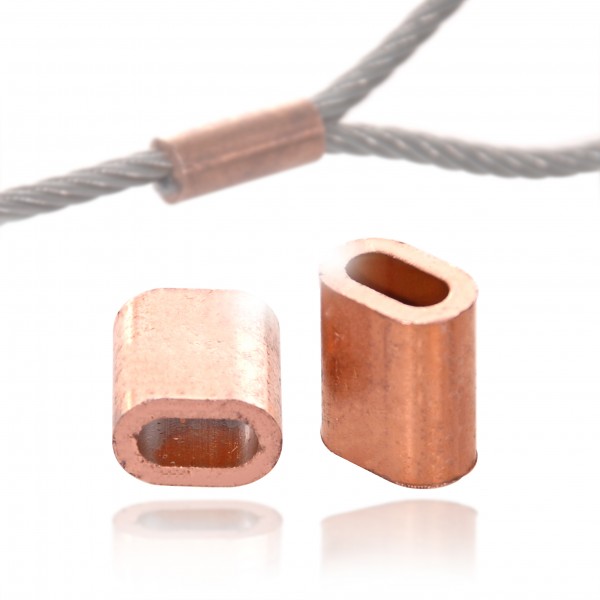

Wire Rope Ferrule Copper DIN EN 13411-3

Wire Rope Ferrule Copper DIN EN 13411-3

from

€1.30

Prices incl. VAT incl. shipping costs

Ready to ship today,

Delivery time appr. 1-3 workdays

Ready to ship today,

Delivery time appr. 1-3 workdays

Please configure the product.

- Categories: Wire Rope & Steel Cable Accessories , ...

- Order number: DS10110

- Weight: 0.005 kg

Production according to DIN EN

Optimally suitable for self-assembly

Available from 1 piece

Optimally suitable for crimping pliers

We are offering the possibilty to return the products for 100 days.

We use only high quality industrial steel for our wire ropes.

We construct our wire ropes according to DIN european norms.

We can offer know-how from over 25 years in Wire-, securing and stop ropes.