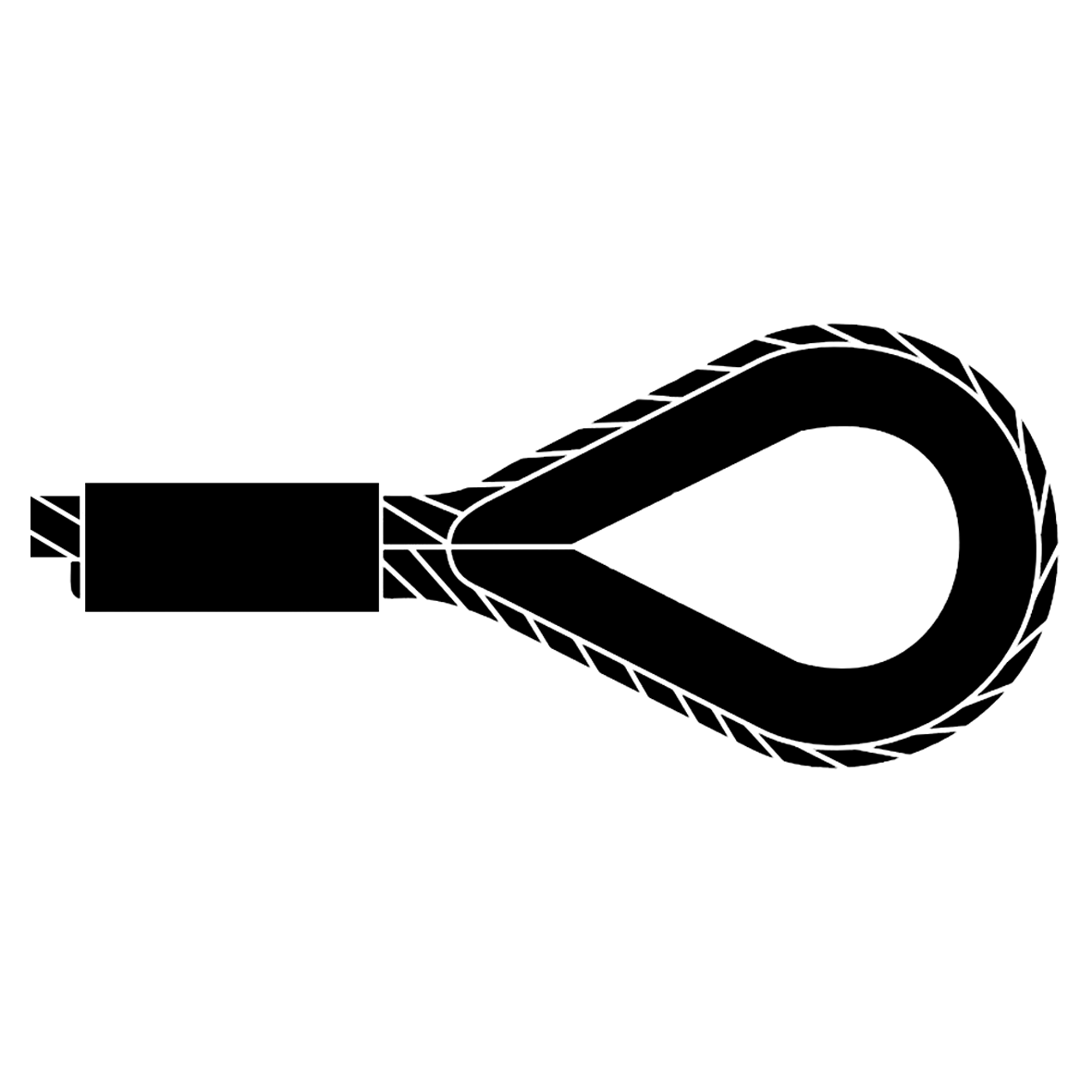

Wire Rope PVC Coated with Thimble

Wire Rope PVC Coated with Thimble

from

€8.80

Prices incl. VAT incl. shipping costs

Ready to ship today,

Delivery time appr. 1-3 workdays

Ready to ship today,

Delivery time appr. 1-3 workdays

Please configure the product.

- Categories: PVC coated Wire Rope , ...

- Order number: DS10314

- Weight: 0.02 kg

Special length possible

Crimped rope thimbles for internal protection of the wire rope

Calculated safety factor for breaking force

1-2mm thick PVC plastic sheathing

We are offering the possibilty to return the products for 100 days.

We use only high quality industrial steel for our wire ropes.

We construct our wire ropes according to DIN european norms.

We can offer know-how from over 25 years in Wire-, securing and stop ropes.